Dive into the captivating world of development: Hardware and Software, two fundamental terms in the field. Explore their definitions, roles, and understand their crucial importance in the functioning of our modern world.

What is hardware?

Hardware, also known as computer hardware, represents all the physical components of a computer system. This includes electronic devices, integrated circuits, peripherals, hard drives, memory, motherboards, processors, monitors, keyboards, mice, printers, etc. In other words, hardware refers to everything you can see and touch in a computer or electronic device. It is responsible for executing software instructions and processing data.

Hardware is essential for the proper functioning of a computer system. It is designed to perform specific tasks and enable the execution of software. Without hardware, software could not function, and computers would not exist.

And what about software?

Software encompasses all the programs, data, and instructions that control the functioning of a computer system, in summary: the software. It consists of codes written in various programming languages, such as C++, Java, Python, etc. Software can be divided into two main categories: operating systems and applications.

Operating systems, such as Windows, macOS, and Linux, are software that manages a computer's resources and allows users to interact with the hardware. They are responsible for file management, memory allocation, device management, etc. Applications, on the other hand, are software designed to perform specific tasks, such as word processing, photo editing, internet browsing, etc.

Software plays an essential role in the functioning of a computer system. It allows users to interact with the hardware and perform specific tasks. Without software, computers could not operate, and hardware would be useless.

Their role in our modern society

Both hardware and software are essential in our daily lives, where computers and electronic devices play a central role. Hardware provides the physical foundation necessary for the functioning of computer systems, while software offers the instructions and programs needed to perform various tasks.

Hardware is important because it determines the performance and capabilities of a computer system. High-quality and powerful components can improve processing speed, storage capacity, and graphic quality of a computer. Furthermore, hardware is often designed to be scalable, meaning it can be upgraded to meet the changing needs of users.

Software is just as important because it allows users to interact with the hardware ergonomically. It enables the execution of various tasks, whether it be writing documents, editing photos, watching videos, or browsing the internet... Software is also regularly updated to improve functionality, security, and compatibility of computer systems.

In summary, hardware and software complement each other and are indispensable for the proper functioning of computer systems. Whether you are a developer, a user, or simply curious, understanding this distinction will help you better appreciate the importance of these two terms in our modern technological society.

Industrial hardware and software

In the industrial field, hardware and software play a crucial role in the development and functioning of automated systems. Regardless of the sector, these two elements are essential for optimizing processes and ensuring efficient production.

Industrial hardware consists of various equipment such as sensors, actuators, robots, and machines. These physical components are designed to collect data, perform tasks, and monitor operations. For example, in a manufacturing plant, industrial hardware will include automated machines that assemble products and sensors that measure production levels and control machine movements.

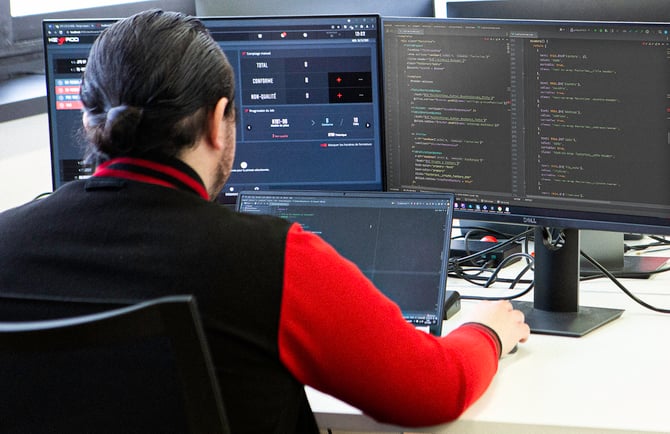

Industrial software, on the other hand, is responsible for programming and managing these automated systems. It includes supervisory software, control systems, and user interfaces to manage industrial operations. Thanks to software, it is possible to program action sequences, collect and analyze data in real-time, and optimize production processes.

The interaction between hardware and software in industry enables the automation of repetitive tasks, improvement of productivity, reduction of human errors, and optimization of resource use. For example, in the logistics sector, warehouse management systems use both hardware and software to track and organize inventory, optimize delivery routes, and manage the flow of goods.

At KEYPROD, we understand the importance of these two aspects in the industry. That's why we develop IIOT (Industrial Internet of Things) solutions that integrate both hardware and software. Working closely with our clients, we design production tracking systems that meet their specific needs. Thanks to our expertise in both hardware and software development, we can offer comprehensive and integrated solutions for the industry.

In conclusion, hardware and software are essential components in modern industry. Their interaction allows for the automation of processes, improvement of productivity, and optimization of resource use. At KEYPROD, we are proud to contribute to the development of the technological industry by offering high-quality IIOT solutions, both in terms of hardware and software and especially Made in France.