As industrialists, you're familiar with your losses, at least intuitively and through experience. But are they quantified accurately and automatically? If not, you might be fighting the wrong battles (tackling non-priority stoppage causes), or even missing major losses entirely (accumulation of micro-stoppages).

What is the Pareto Principle?

We're all aware that there are numerous time losses in the production process. Machine stops, breakdowns, adjustments, maintenance...

How long do these stops actually last?

To find out, it's necessary to clearly identify the origins of the losses, record the causes of stops occurring on equipment, because we can only improve what we can measure.

Everyone knows the Pareto principle, this column chart that highlights the few causes that have the most impact in a company. The size of each column is proportional to the impact of each issue.

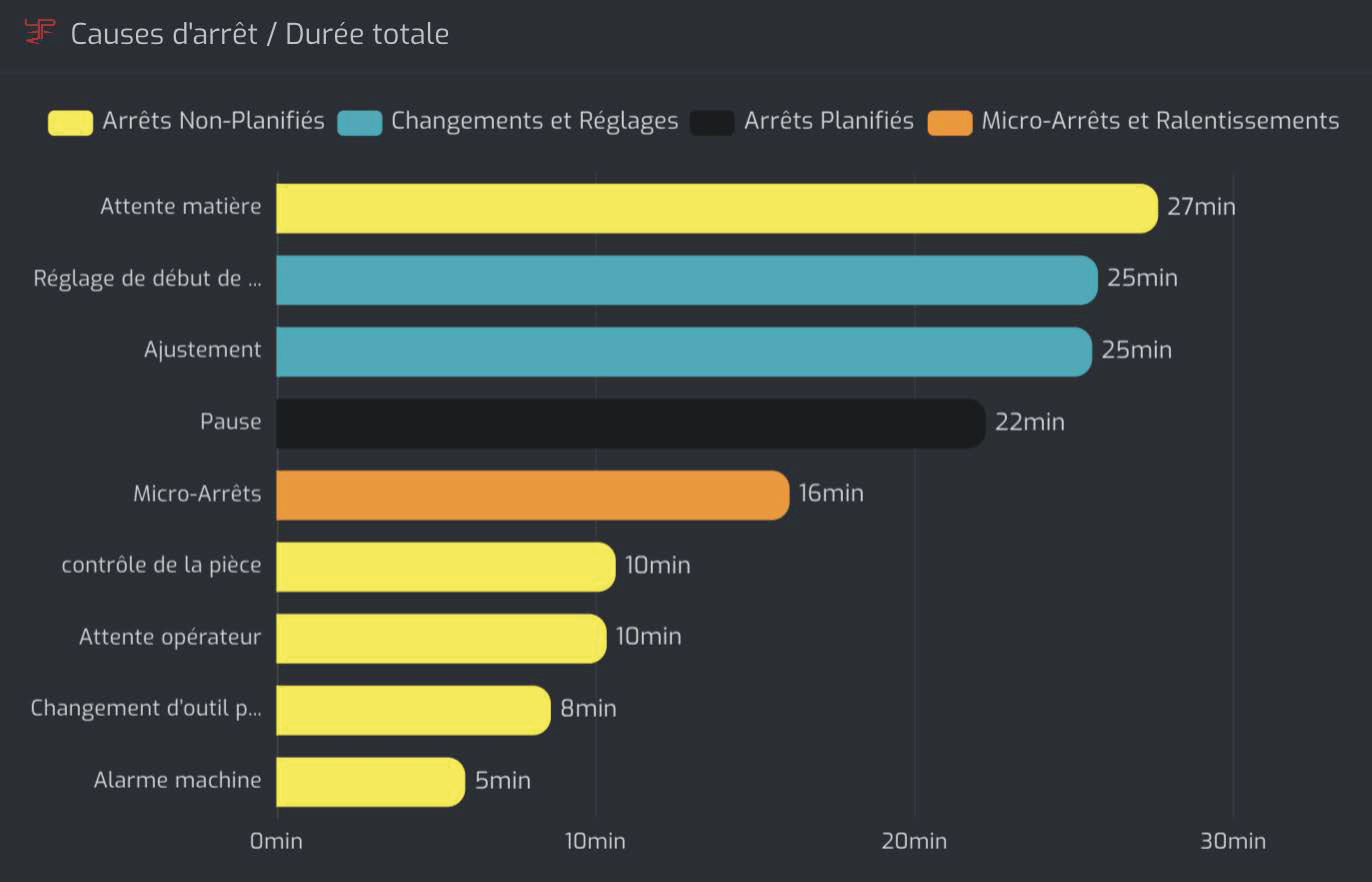

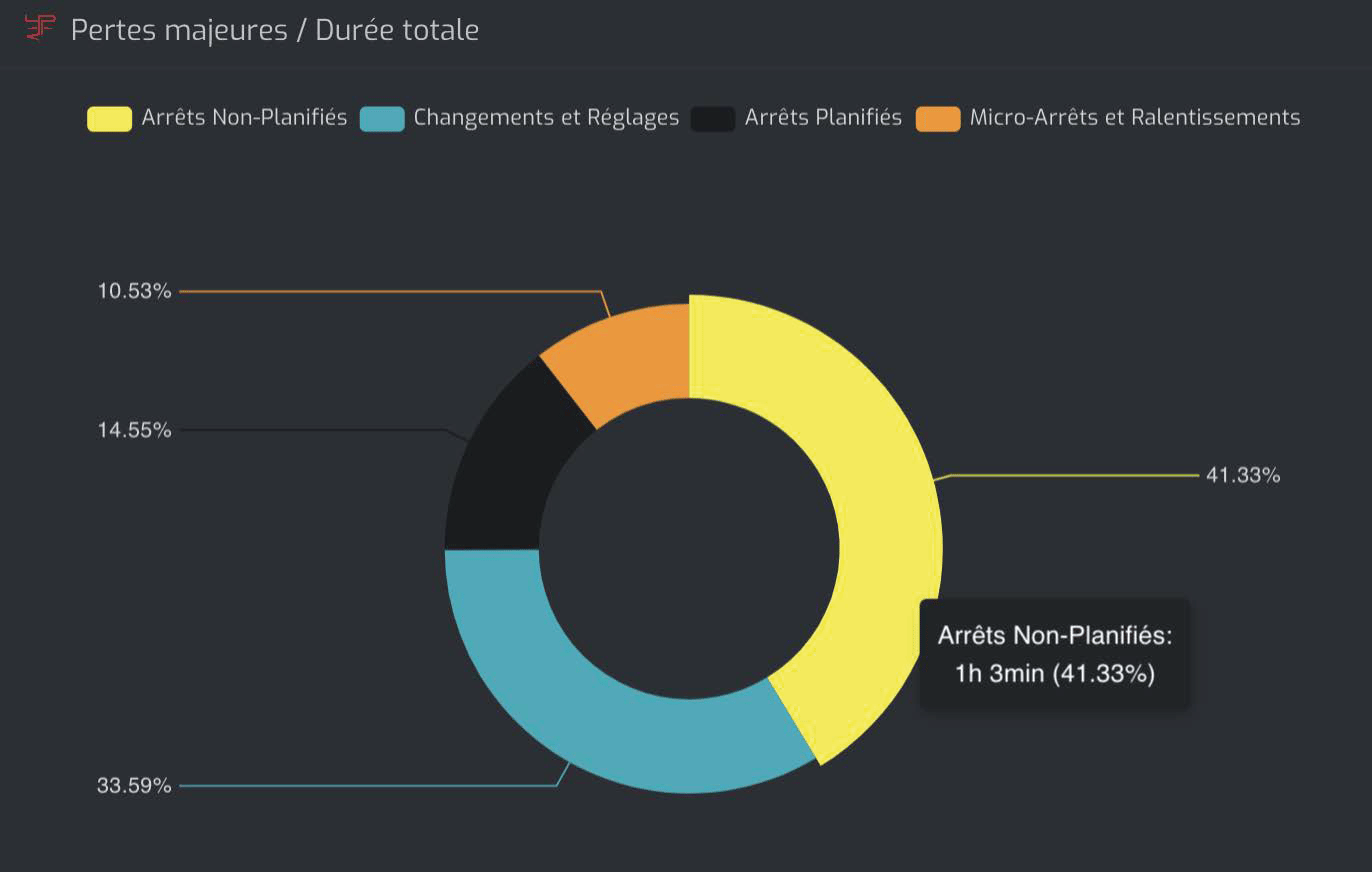

In the industry, the Pareto principle is primarily used to highlight the causes that generate the most losses. It allows for easy display and measurement of productivity loss sources by quantifying the number of occurrences or the total time taken by a cause of breakdown, for example. Thus, the production manager or methods can easily identify the stops generating the most losses, by machine, by team (...) and therefore target the improvement areas to deploy as a priority for the company.

Because YES: Analyzing the causes of non-production is the foundation of productivity improvement!

How to implement a Pareto?

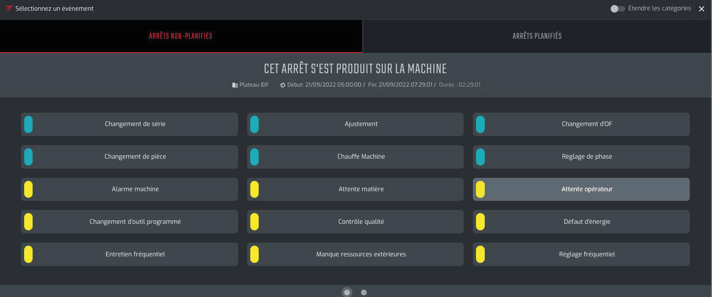

This is where we come in! KEYPROD allows you to easily set the names of major stop causes you observe or want to measure, according to the following five major categories:

➡️ Planned stops

➡️ Unplanned stops

➡️ Breakdowns

➡️ Changeover and adjustments

➡️ Micro-stoppages

Then, in less than 15 minutes, you have a solution that aggregates all information from the field in real-time. How? Thanks to the collaboration of our smart devices and your operators. KEYPROD provides them with a simple interface that allows them to categorize the causes of non-production precisely in two clicks!

The "declared" losses (unplanned, breakdowns, series changes and adjustments), the "programmed" (planned stops) and the "predefined" (micro-stoppages - production) by our devices, are then cumulated and automatically ranked.

In summary, identifying and analyzing a Pareto of losses creates a list of priority actions to quickly improve the performance of your production workshop.