BCM Métallerie, a subsidiary of Global Metal Works and a recognized expert in metal transformation through machining and forming, as well as in assembly, has embraced Industry 4.0. This was an opportunity seized by the industrial company, wishing to deploy the digitization of its production. By calling on KEYPROD and our 4.0 production monitoring solutions, BCM Métallerie implemented the management of its workshop.

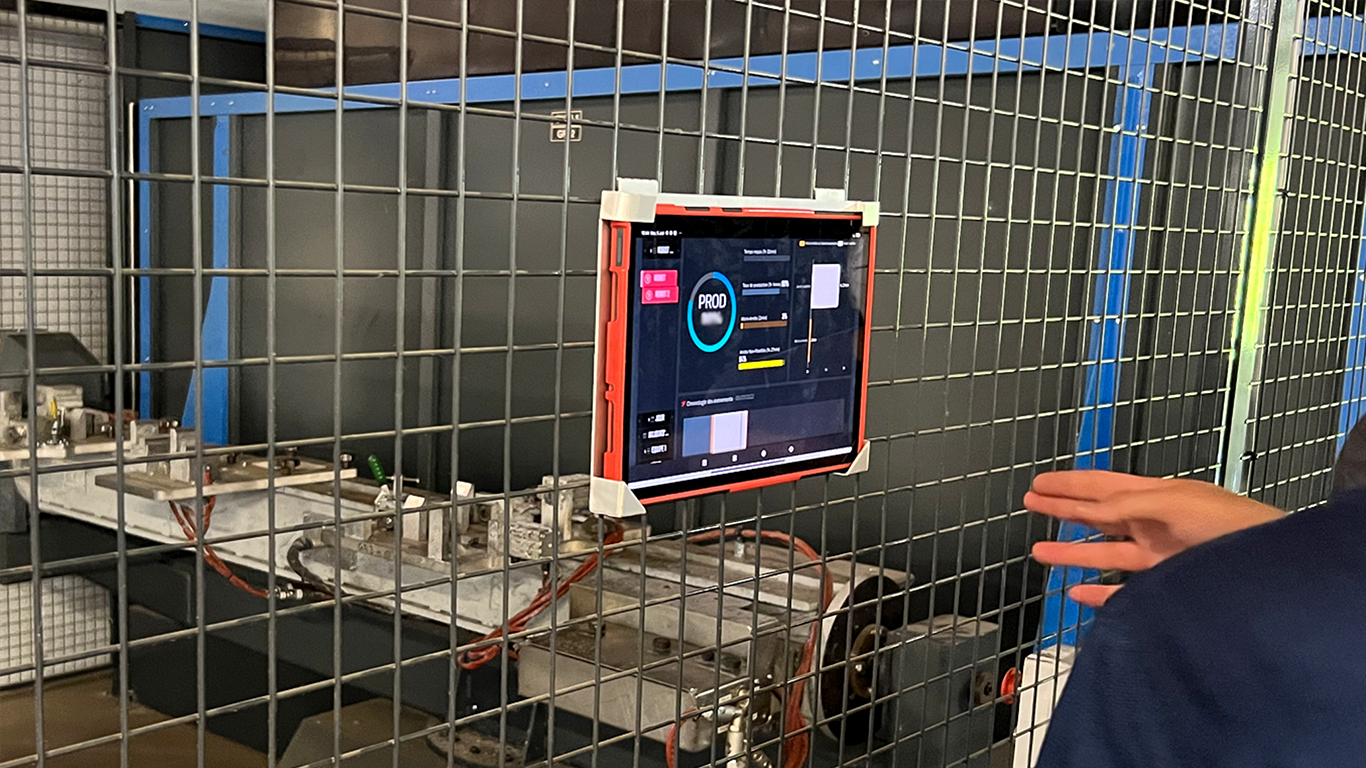

After a successful testing phase, several KEYVIBE units were deployed on various types of machinery:

👉 Laser cutting,

👉 Welding robot,

👉 Punch press,

👉 Wood machining.

Today, BCM Métallerie shares its experience through the testimony of Luc FERNANDEZ, General Manager.

Benefits of the KEYPROD Solution

"KEYPROD is among the new essential needs of modern industries. It allows small and medium-sized enterprises, such as SMEs and small ETIs, to provide reliable, real-time indicators crucial for production monitoring, all in a fully digitalized manner.

KEYPROD has enabled us to enhance the skills of workshop managers and production/quality supervisors. Data analysis has generated significant interest from our operators and technicians, who have seen the benefits of their work!"

Initial Benefits Observed

"The first results are quick; we have already seen a productivity gain of 2 to 5% on equipment types such as welding robots and machines for Aluminum/Wood/Composite and laser cutting. After just a few weeks, we observed a significant cooperative and collaborative surge among teams in analyzing machine stoppage causes and the associated work to reduce or eliminate them. All industrial services are concerned, consulted, and involved (maintenance, quality control, production, supply, and improvement methods)."

In Summary, KEYPROD is...

"A simple, quick deployment with playful and very easy-to-use interfaces. New features are currently being developed to better follow scheduled manufacturing orders. And finally, sales and technical teams that are attentive, supportive, and responsive!"